Published Articles

Automation World – Guest Blogger

Renown for editorial excellence, Automation World covers the entire spectrum of industrial automation technologies, software and devices. AW reports on developments in discrete manufacturing, batch/hybrid processing and continuous process operations and also produces the annual Automation World Conference & Expo.

How manufacturing execution system technology provides the data context, data access and data insights to help operators and plant leadership deliver results and improve upon them daily.

How manufacturing execution system technology provides the data context, data access and data insights to help operators and plant leadership deliver results and improve upon them daily.

Early discussions between integrators and manufacturers that focus on too many preconceived approaches or preconfigured software can limit capabilities, lead to a lack of engagement and impact the success of the program before it starts.

Early discussions between integrators and manufacturers that focus on too many preconceived approaches or preconfigured software can limit capabilities, lead to a lack of engagement and impact the success of the program before it starts.

Manufacturing execution systems have long been recognized as middleware between plant floor control systems and enterprise systems. But they also serve as a middleman for data translation and structuring plant floor data for use by MES applications.

Manufacturing execution systems have long been recognized as middleware between plant floor control systems and enterprise systems. But they also serve as a middleman for data translation and structuring plant floor data for use by MES applications.

Learn more about Digital Transformation through the lens of expert Bruce Slusser. Here he talks about his thoughts on where the space is going, where he sees it going, what to watch out for on your Digital Transformation journey and the best time and project situation to consider working with an expert.

Learn more about Digital Transformation through the lens of expert Bruce Slusser. Here he talks about his thoughts on where the space is going, where he sees it going, what to watch out for on your Digital Transformation journey and the best time and project situation to consider working with an expert.

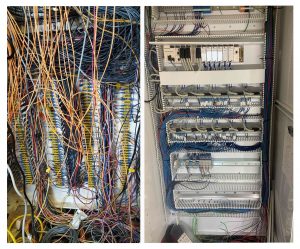

Following the manufacturer’s guidelines when swapping out PLC hardware will only get you part of the way to a successful controller upgrade. I/O card issues, rack space, communications, and octal to decimal conversions are also important.

Following the manufacturer’s guidelines when swapping out PLC hardware will only get you part of the way to a successful controller upgrade. I/O card issues, rack space, communications, and octal to decimal conversions are also important.

Upgrading human-machine interface hardware and software amid industry’s digital transformation is rarely the direct replacement process it once was. System integrators offer valuable insights into evaluating your options.

Upgrading human-machine interface hardware and software amid industry’s digital transformation is rarely the direct replacement process it once was. System integrators offer valuable insights into evaluating your options.

Control Engineering

Transforming raw data into valuable, actionable insights in real-time is a complex task that necessitates advanced technologies and edge computing can help with the process.

PLC standards have greatly changed since the 1980s. Learn how modern programming tools have greatly improved PLC development.

Operational improvement can be met by digging into each step of the equipment’s timing, accuracy and causes of process step disruption by analyzing the raw data.

Many manufacturing facilities are taking on digital transformation initiatives, and long-term maintenance and support needs to be prioritized.

Ethernet is a robust and stable network framework that has more possibilities than other networking protocols.

The upgrade process for a PLC-5 is relatively easy and can enable organizations and employees to do things they have not yet thought of.

Additional Publications

Avanceon’s President Matt Ruth spoke about importance of connecting all assets together from Ethernet to OT. He explains that this connection allows manufacturers to have a greater insight into the equipment itself.

Avanceon’s President Matt Ruth spoke about importance of connecting all assets together from Ethernet to OT. He explains that this connection allows manufacturers to have a greater insight into the equipment itself.

As cyber attacks escalate, the food and beverage sector eyes a fresh course of action to safeguard operations and prevent disruptions to the supply chain.

Avanceon’s Brian Fenn outlines how manufacturing organizations can optimize their existing Microsoft technology investments to gain new insights from the data they already gather.

Avanceon’s Brian Fenn outlines how manufacturing organizations can optimize their existing Microsoft technology investments to gain new insights from the data they already gather.