Why Every Plant Should Consider a SCADA Check-Up

Blog

30 September 2025Why Every Plant Should Consider a SCADA Check-Up

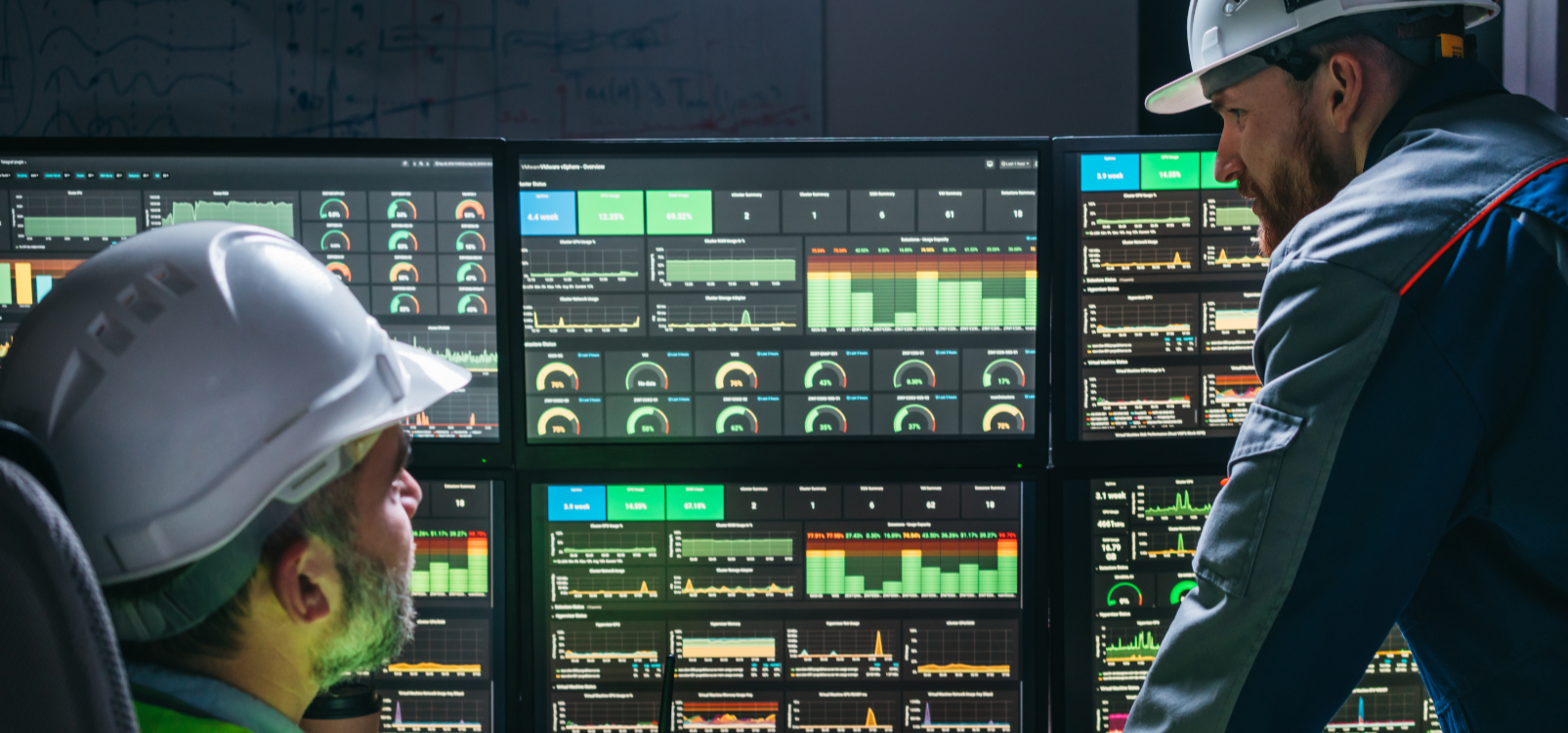

Every plant has a SCADA system, but not every plant takes the time to evaluate how well it is really working. Operators know the signs: navigation that feels cluttered, alarms that never stop, or screens that take just a little too long to respond. Over time, these small inefficiencies build up quietly. Things that could be fixed often go unaddressed as operators learn to live with them, relying on workarounds that keep production moving but add frustration and reduce efficiency.

Actemium’s SCADA Check-Up provides a structured way to review the system, highlight gaps, and identify improvements that will make the system more effective and sustainable. The Check-Up focuses on important categories like usability, performance, security, and others. Each focus area is assessed through structured questions and scored using a weighted rubric. This provides a clear, objective measure of how the system is performing across multiple dimensions. Here are a few of the focus categories to provide some insight into our approach.

Usability & Navigation

We assess how easy it is for operators to move through the system and reach the functions they use most often. This includes looking at how many steps it takes to perform common tasks, whether functions are grouped together logically, and if the primary screens used by operators are clear and intuitive. Navigation should be efficient and reliable, with links and buttons that consistently work as intended.

Example Question: How many steps are required to access commonly used functions and what impact does this have on daily efficiency?

Performance & Expandability

We assess how well the SCADA system responds during daily use and under heavier loads. This includes measuring how quickly screens update, how long it takes to retrieve historical trends and reports, and whether the system shows signs of server or network strain. We also evaluate if the current architecture has room to grow, supporting future lines and equipment without major disruption.

Example Question: Can operators and engineers access historical trends and reports fast enough to support timely decision-making?

Operator Focus

We assess how effectively the system supports operators in making quick and accurate decisions. This includes reviewing the use of color, flashing, and other visual elements to determine whether they highlight critical conditions or simply create distraction. Alarm activity is also evaluated to see if operators are dealing with floods of nuisance alarms or if events are categorized and prioritized in a way that helps them respond efficiently. Consistency in screen design is another factor, ensuring operators are not slowed down by unnecessary variation from one part of the system to another.

Example Question: Do visual and alarm elements help operators focus on what truly matters in the moment?

Security & User Management

We assess how user accounts and access rights are structured and maintained within the SCADA system. This includes looking at whether accounts are regularly reviewed, if permissions match user roles, and whether there is a clear process for adding or removing users. We also evaluate who is responsible for managing security and whether controls are in place to prevent unauthorized access. Strong user management ensures the system is protected without creating unnecessary barriers for the people who need it.

Example Question: Are account permissions structured in a way that both protects the system and supports productivity?

Integration & Data Usage

We assess how the SCADA system fits within the larger automation and business environment. This includes evaluating how well it connects with systems such as MES, ERP, and historians, and whether multiple SCADA or HMI platforms are in use across the plant. We also look at who outside of operations relies on SCADA data, what information they need, and how they currently access it. Understanding these connections helps reveal where integration is strong, where gaps exist, and how data can be better shared across the organization.

Example Question: Who else relies on SCADA data, and are they getting what they need in a timely way?

Bringing It All Together

Actemium’s full SCADA Check-Up is a structured evaluation designed to give you a complete picture of your system. It includes:

- 30 structured questions across ten categories, including governance, training, and physical conditions.

- Objective scoring through a weighted rubric to show where your system excels and where it lags.

- Actionable analysis with scores translated into practical insights.

- Prioritized recommendations that balance quick wins for operator quality of life with long-term improvements that maximize ROI.

The result isn’t just a report, it’s a roadmap for making your SCADA more effective, secure, and ready for future growth.

A Better System, Starting Now

A SCADA Check-Up is a small investment that delivers a high reward. By taking the time to benchmark your system now, you can:

- Make life easier for operators.

- Strengthen system reliability.

- Position your plant for future growth.

Schedule your SCADA Check-Up today and start unlocking the reliability, efficiency, and operator confidence your plant deserves.

Written by: Nicholas Imfeld

Blog, SCADA